How Does Conduction Cooling Keep Heat in Check? – 8400530

Keeping Heat in Check: Conduction Cooling Expands Application Boundaries

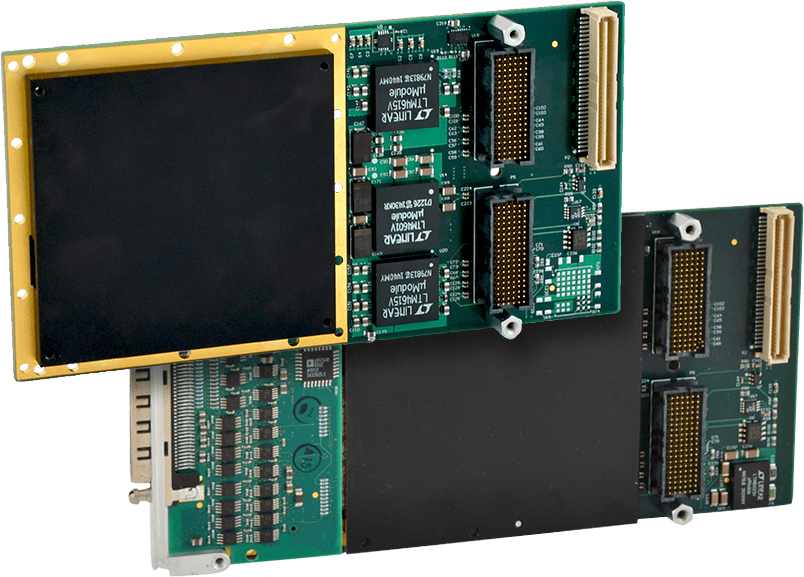

Current application demands of XMC Mezzanine Card (XMC) modules have grown from the simple addition of I/O and low-level communications to the servicing and off-loading of high performance software defined radio (SDR), digital signal processing (DSP), co-processing, and now re-configurable FPGA-based computing with gigabit interfaces. This trend of putting more and more processing power on XMC modules has led to new challenges keeping these computer hot rods cool. Standard, or commercial-grade, modules typically accommodate operation in lower temperature environments while industrial-grade models will tolerate a higher temperature range. However, many applications require additional steps to keep board temperatures within

acceptable ranges.

High performance computing applications generally consume more energy and thus generate more heat, yet these same applications often require condensation into smaller physical sizes which complicates cooling. When these electronics are installed in mobile military machinery such as Humvees, tanks and UAVs which are regularly exposed to extreme environments, the risks of overheating are compounded. Uncontrolled heat buildup can quickly destroy high priced computers.

A number of technologies have been developed to deal with heat buildup, including forced air cooling, conduction cooling, and liquid cooling. Of these strategies, conduction cooling is the one technology which has been deployed and standardized to meet these new demands and make it possible for system design engineers to keep generated heat in check.

The ANSI/VITA 20 Conduction-Cooled XMC (CCXMC) Specification is designed so that heat generating components on XMC modules are connected to metallic thermal planes within the XMC. These thermal planes connect to a conduction-cooled ring surrounding an area dense with high-energy components. In conventional conduction-cooled applications, I/O is mapped to the rear I/O connector and front I/O is not used.

Click here to download the complete PDF of How Does Conduction Cooling Keep Heat in Check?

More resources:

What is AcroPack FPGA Module with Zynq UltraScale+ MPSoC? | Technology Paper

What are FPGAs and FPGA Applications? | Webcast Replay (part 1 of FPGA series)

How to Use Vivado for FPGA Modifications | Webcast Replay (Part 2 of FPGA series)

What is Zync UltraScale+ MPSoC? | Webcast Replay (Part 3 of FPGA series)